A superconducting* USB-c cable

Published:

Maker culture meets computer DIY and high-energy physics

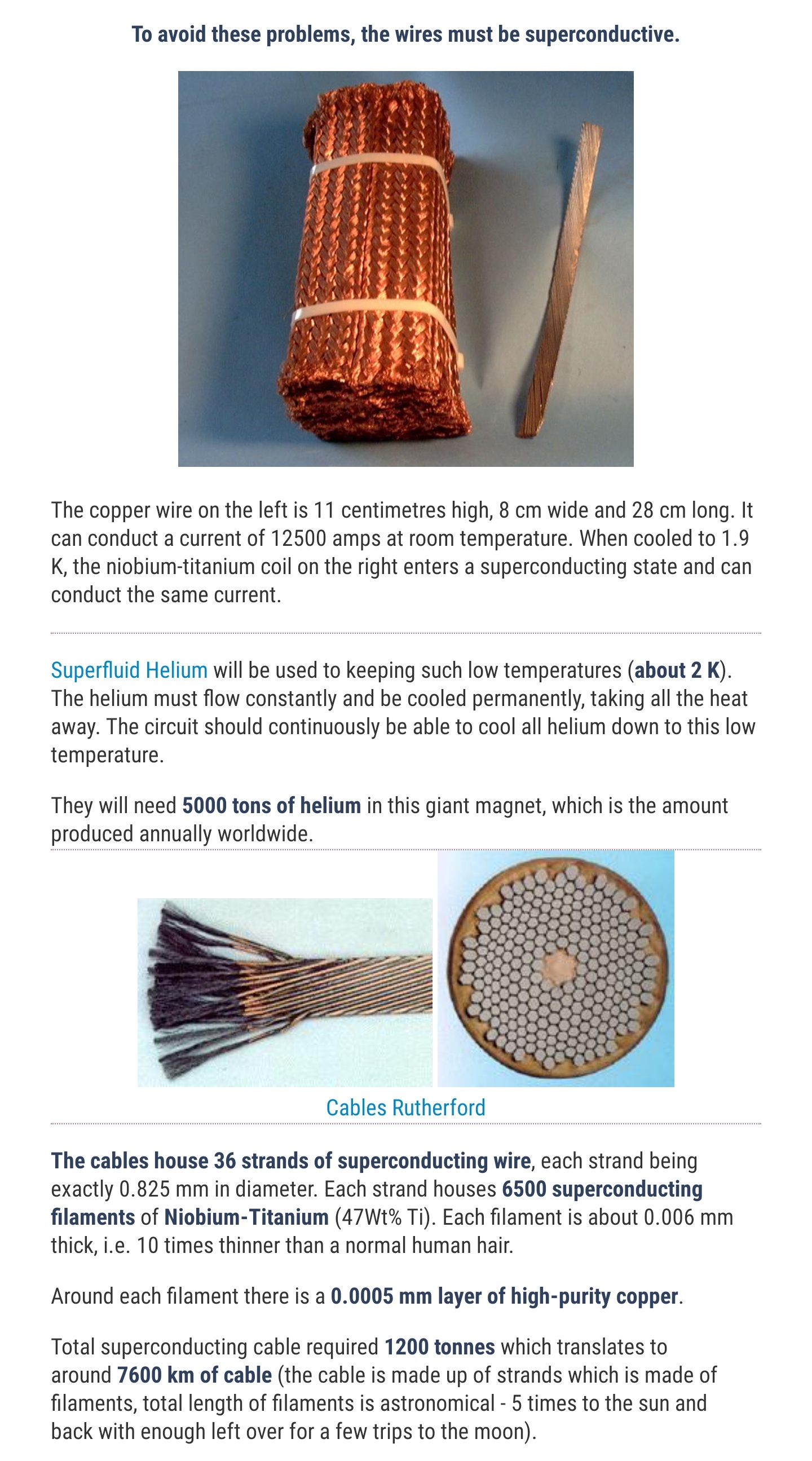

A dear friend and fellow computer hobbyist was finishing his gargantuan PhD thesis so I wanted to make something personalized as a gift. A natural choice was to make a custom mechanical keyboard cable, since we keyboard connoisseurs appreciate a beautiful usb cable, and I had built him my vision of the ultimate data scientist mechanical keyboard. But what is a thematically fitting cable part or component for a fresh doctor of theoretical particle physics? Well, I thought that the superconducting Titanium–Niobium wire that has been used in the superconducting magnets in the Large Hadron Collider would fit the bill. I asked around a little, and was able to acquire a sample of the original wire which was manufactured by a Finnish company:  In room temperature this acts as a highly pure copper wire with a thin tin anti-corrosion layer, and the Ti–Nb fibers that become superconducting in very cold temperatures (~2K) are encased within each wire of the bundle shown in the above photo.

In room temperature this acts as a highly pure copper wire with a thin tin anti-corrosion layer, and the Ti–Nb fibers that become superconducting in very cold temperatures (~2K) are encased within each wire of the bundle shown in the above photo.

How does one make a USB cable out of raw uninsulated electrical conductor?

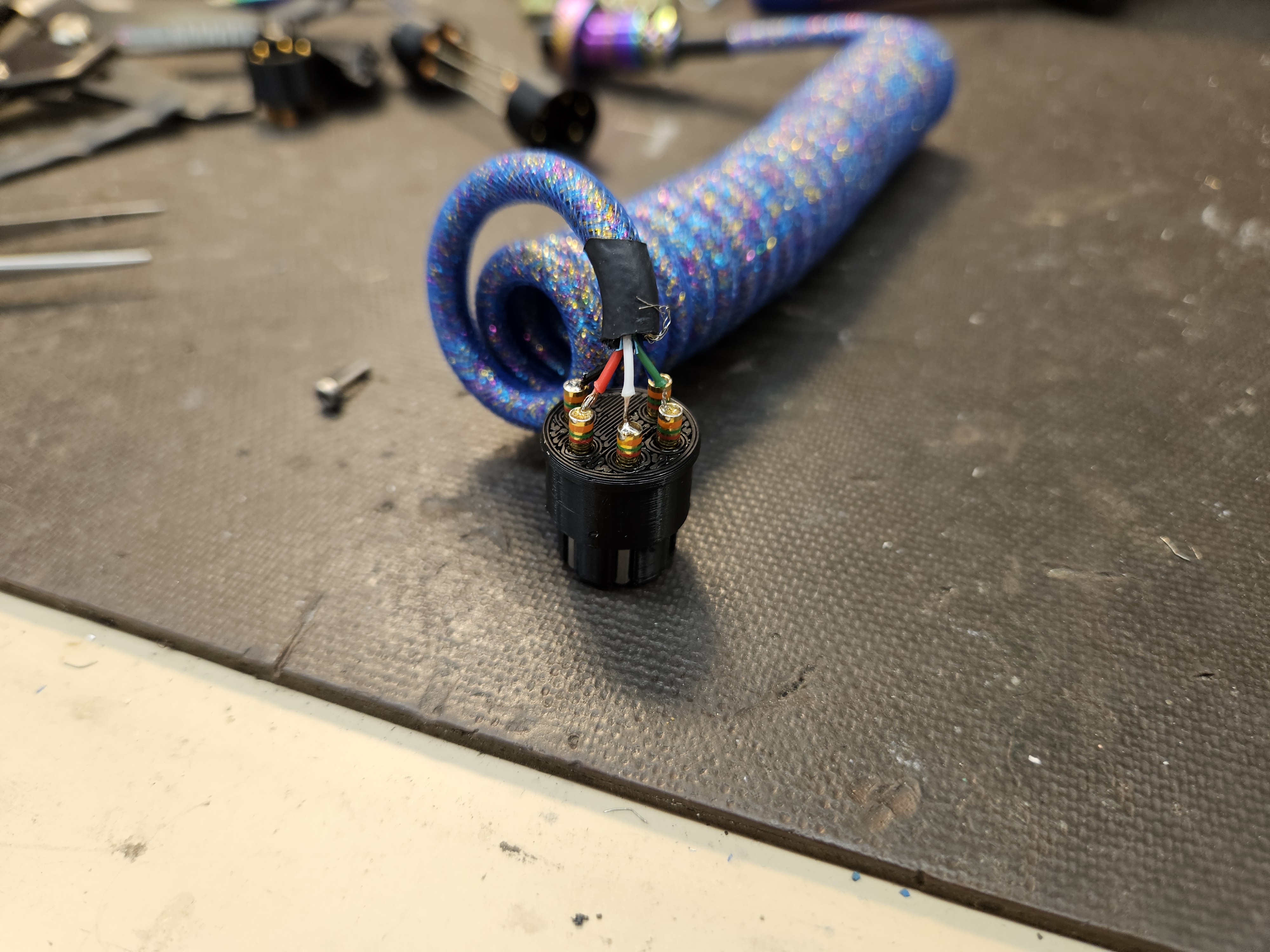

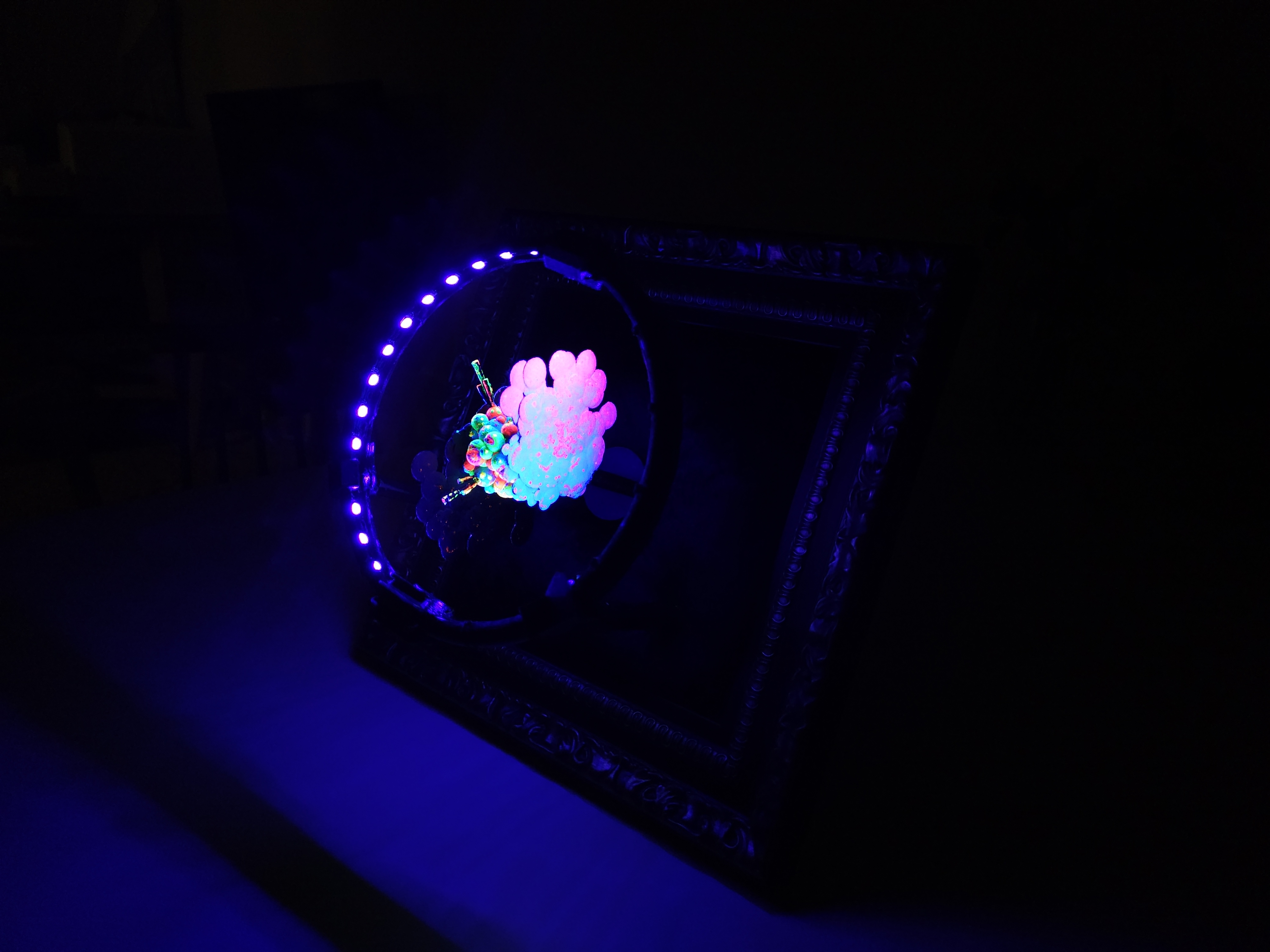

It required a little creative thinking. The first requirement was that the power and usb data should really go through the Ti–Nb conductor. Second was that the special artifact of a wire should be installed in an appropriately exquisite manner, like one mounts gemstones in golden settings. This would turn out to be a huge rabbit hole and the hardest part of the whole thing: where to get golden connector terminal pins to install the wire in without ordering lots of 1000 units, or some other nonsense. Hours of searching over weeks/months went by, and ultimately I asked help from my electronics course lecturer who was kind enough to invite me to the workshop at the physics department to discuss my plan. As luck would have it, he knew where to get some nice gold plated terminals, and I only needed to design and 3D print custom connectors for the pins, and to install the glass tube onto the usb cable. Oh yeah, the third requirement of course was that the magnificent Ti–Nb wire with its gilded settings should be visible to the user, as per usual. A baker’s dozen iterations later I had figured out the 3D printed connector parts, and I could finally solder everything together, which the electronics course lecturer graciously let me do in the electronics workshop of the particle accelerator lab. I had to wait until the kids were at bed to be able to finish assembling the cable to test it, and would you believe it because I couldn’t, it worked like a charm on the first try. I suppose that’s plug and play for you.